Steel structures are the backbone of modern construction, powering everything from sprawling industrial complexes to innovative commercial buildings. The process of fabrication plays a crucial role in ensuring the strength, efficiency, and versatility of these structures. In this article, we explore how fabrication enhances steel structure jobs, with a special focus on the expertise and innovations of Grup Honglu (disingkat menjadi Honglu), a leading name in the industry.

Understanding Fabrication in Steel Structures

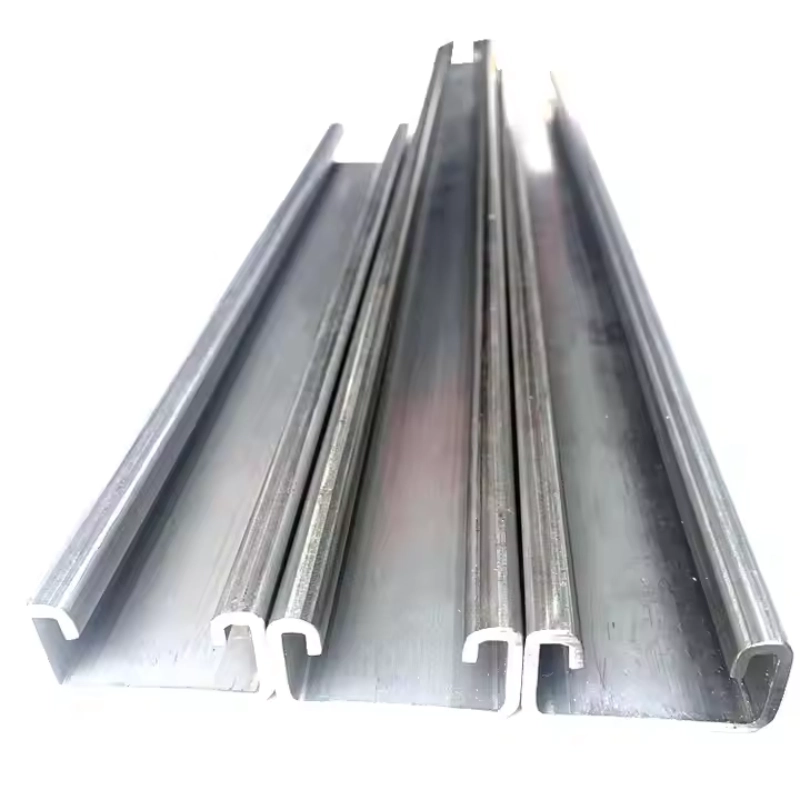

Fabrication involves transforming raw steel into specific shapes and components through cutting, bending, welding, and assembling. This process is foundational to the construction of both industrial steel structure and pre engineered steel structure projects. Effective fabrication ensures that steel components meet exact design specifications, resulting in safer, more reliable, and cost-effective structures.

- Precision engineering for high-quality output

- Customization to meet project-specific requirements

- Enhanced durability and longevity of structures

The Role of Honglu Group in Steel Structure Fabrication

Grup Honglu has established itself as a pioneer in steel structure fabrication, leveraging cutting-edge technology and a team of skilled professionals. With decades of experience, Honglu specializes in delivering tailored solutions for a wide range of projects, from industrial warehouses to commercial buildings.

Their fabrication facilities are equipped with advanced machinery, enabling high-precision manufacturing and efficient workflow management. This commitment to innovation allows Honglu to consistently deliver superior results, setting new benchmarks in the steel structure industry.

Key Advantages of Honglu’s Fabrication Process

- Jaminan Kualitas: Rigorous quality control protocols ensure every component meets international standards.

- Kustomisasi: Honglu offers bespoke solutions, adapting fabrication processes to the unique needs of each client.

- Efisiensi: Streamlined workflows and automation reduce lead times and minimize waste.

- Keberlanjutan: Eco-friendly practices, including recycling and energy-efficient operations, are integrated into every project.

Enhancing Industrial Steel Structure Projects

The fabrication process is particularly vital in industrial steel structure projects, where strength, safety, and scalability are paramount. Honglu’s expertise ensures that each steel component is engineered to withstand heavy loads, harsh environments, and demanding operational conditions.

By adopting modular fabrication techniques, Honglu enables quicker assembly on-site, reducing construction time and labor costs. This approach not only accelerates project timelines but also enhances safety by minimizing the duration of on-site work.

Industry Application Example

One standout example is the construction of large-scale logistics centers. Honglu’s fabricated steel structures offer vast column-free spaces, allowing for flexible layouts and efficient storage solutions. Their robust design also supports the integration of advanced material handling systems, further boosting operational efficiency.

The Rise of Pre Engineered Steel Structures

The demand for pre engineered steel structure solutions has surged in recent years, driven by the need for rapid construction and cost savings. Honglu has been at the forefront of this trend, offering pre-engineered systems that combine high performance with design flexibility.

- Factory-fabricated components for precise assembly

- Reduced on-site construction time

- Lower overall project costs

Honglu’s pre engineered steel structures are widely used in industrial parks, sports arenas, and commercial developments. Their ability to deliver consistent quality and adaptability makes them an ideal choice for developers seeking efficient, scalable solutions.

Broader Industry Trends and Innovations

The steel structure industry is undergoing rapid transformation, with digitalization, automation, and sustainability driving new advancements. Companies like Honglu are investing in Building Information Modeling (BIM), robotic welding, and AI-powered quality control to enhance fabrication accuracy and project management.

Furthermore, there is a growing emphasis on green building standards. Fabrication processes are being optimized to reduce carbon footprints, recycle materials, and improve energy efficiency. Honglu’s commitment to sustainable practices positions them as a leader in this evolving landscape.

Challenges and Opportunities

- Adapting to evolving safety and environmental regulations

- Integrating new materials and hybrid construction methods

- Meeting rising demand for customization and rapid delivery

As the industry continues to innovate, the role of fabrication will only grow in importance, shaping the future of both traditional and pre engineered steel structure projects.

Conclusion: The Future of Steel Structure Fabrication with Honglu

In summary, fabrication is the cornerstone of successful steel structure projects, enhancing quality, efficiency, and adaptability. Through its unwavering commitment to innovation and excellence, Grup Honglu stands at the forefront of the industry, delivering world-class solutions for industrial steel structure and pre engineered steel structure needs.

As construction demands evolve and sustainability becomes a top priority, companies like Honglu will continue to drive the industry forward, ensuring that steel structures remain a pillar of modern infrastructure.

Tag::sistem lantai dek,Proyek Struktur Baja Luar Negeri,Garasi Baja & Gudang Baja