In the ever-evolving landscape of industrial construction, sistema de estructura de aceros have become a cornerstone for modern engineering projects. At the heart of every robust steel structure is the beam—an element whose design determines not only the strength and safety of the entire system but also its adaptability to various industrial needs. As a leader in Estructura de acero del equipo OEM and Equipment Steel Structure ODM services, Honglu Group (abbreviated as Honglu) brings a wealth of expertise to the table, ensuring that each project meets the highest standards of quality and innovation.

The Role of Beam Design in Steel Structures

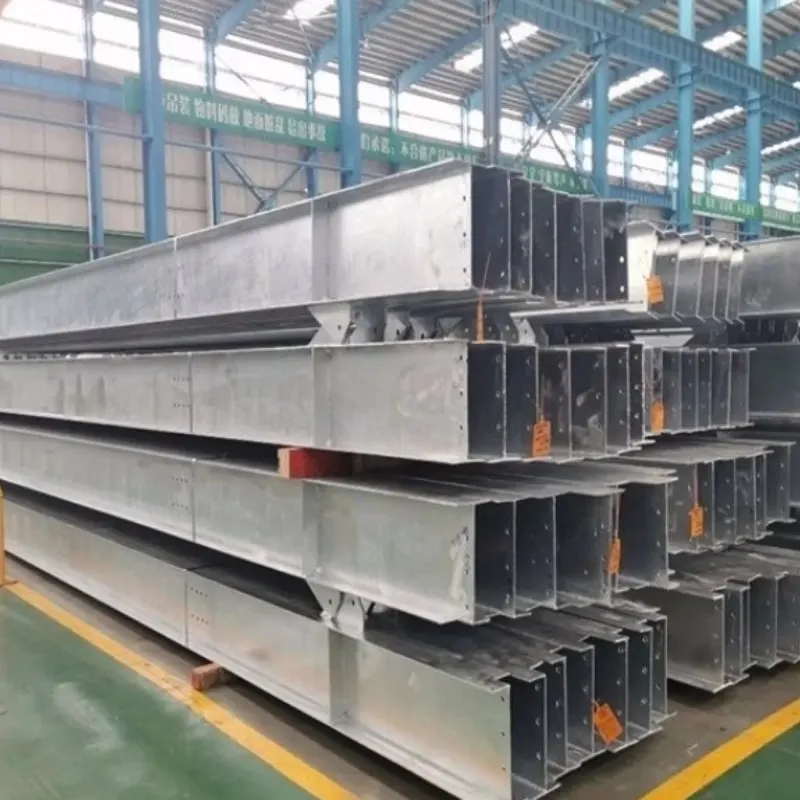

Beams are the primary load-bearing elements in steel structures, responsible for transferring loads from the superstructure to the columns and foundations. Proper beam design is essential to ensure that the building or equipment frame can withstand the stresses imposed by both static and dynamic forces. Inadequate beam design can lead to structural failures, increased maintenance costs, and safety hazards.

For companies like Honglu, which specializes in Equipment Steel Structure OEM and ODM solutions, the importance of precision in beam design cannot be overstated. Whether it's a large-scale manufacturing facility, a warehousing complex, or a custom machinery housing, the beams must be meticulously engineered to accommodate specific operational requirements and load conditions.

Key Considerations in Beam Design

- Load Capacity: Determining the maximum load a beam can safely support is fundamental. This involves analyzing the dead load (weight of the structure itself), live load (weight of equipment, people, and materials), and environmental loads such as wind or seismic activity.

- Selección de materiales: The choice of steel grade and profile directly impacts the beam's performance. Honglu leverages advanced materials and manufacturing processes to deliver beams that offer superior strength-to-weight ratios.

- Span and Deflection: The span of the beam and allowable deflection are critical for maintaining structural integrity and functionality. Excessive deflection can lead to misalignments and operational disruptions, especially in equipment steel structure systems.

- Connection Details: The way beams are connected to columns and other structural elements affects the overall stability of the system. Precision in connection design is essential for both safety and ease of assembly.

Honglu's Approach: Integrating Innovation and Industry Standards

As a prominent Equipment Steel Structure OEM and ODM provider, Honglu integrates the latest industry standards and innovative design methodologies into every project. By utilizing advanced simulation software and adhering to international codes such as AISC, EN, and GB, Honglu guarantees that each beam is optimized for performance and safety.

Moreover, Honglu’s in-house R&D team collaborates closely with clients to customize beam designs for unique industrial applications. This flexibility is especially valuable in the Equipment Steel Structure ODM sector, where tailored solutions are often required to accommodate specialized equipment layouts and operational processes.

Industry Trends and Challenges in Beam Design

The steel structure industry is constantly evolving, driven by demands for greater efficiency, sustainability, and adaptability. Recent trends include the use of high-strength steel alloys, modular construction techniques, and digital twin technologies for real-time performance monitoring. These innovations are reshaping how beams are designed, fabricated, and maintained.

One significant challenge facing the industry is the need to balance cost-effectiveness with safety and durability. With increasing complexity in equipment and facility design, the margin for error in beam engineering has narrowed. Honglu addresses these challenges by investing in continuous staff training, state-of-the-art manufacturing equipment, and rigorous quality control processes.

Advantages of Partnering with Honglu for Equipment Steel Structure OEM & ODM

- Personalización: Honglu offers bespoke beam design services, ensuring that every project aligns with the client’s operational needs and site-specific conditions.

- Seguro de calidad: Every beam undergoes thorough testing and inspection, from raw material selection to final assembly.

- Eficiencia: Advanced manufacturing capabilities enable Honglu to deliver projects on time and within budget, minimizing downtime and maximizing return on investment.

- Technical Support: Clients benefit from comprehensive technical support throughout the project lifecycle, including design consultation, installation guidance, and after-sales service.

Expanding Horizons: The Future of Steel Structure Beam Design

Looking ahead, the steel structure industry is poised for significant transformation. The adoption of AI-driven design tools, smart materials, and IoT-enabled structural health monitoring systems will further enhance the precision and reliability of beam design. Honglu is at the forefront of this evolution, continually exploring new technologies that can deliver safer, more efficient, and more sustainable structural solutions.

For industries requiring Equipment Steel Structure OEM or ODM services, choosing a partner with a strong focus on innovative beam design is more critical than ever. The right design not only ensures safety and compliance but also enables businesses to adapt quickly to changing operational demands and market trends.

Conclusión

In summary, beam design is the backbone of every successful steel structure system. Its impact extends beyond mere load-bearing; it shapes the safety, efficiency, and adaptability of industrial facilities worldwide. Honglu Group’s expertise in Equipment Steel Structure OEM and ODM ensures that clients receive cutting-edge solutions tailored to their exact needs. As the industry continues to evolve, Honglu remains committed to setting new benchmarks in beam design and structural excellence.