As the global demand for sustainable, robust, and cost-effective building solutions grows, prefab steel buildings from China have gained remarkable traction. Honglu Group, often referred to as Honglu, stands at the forefront of this industry, renowned for its commitment to delivering superior construction quality. This article explores the advanced methods, technologies, and materials—such as Carbon U Shaped Steel Channel Steel and C shape steel structure—that enable Honglu to set new benchmarks in prefab steel construction. We’ll also provide a broader perspective on industry trends and innovations.

Precision Engineering: The Foundation of Quality

Honglu’s reputation for excellence begins with its meticulous engineering process. Every prefab steel building project starts with detailed digital modeling and structural analysis, ensuring that every component is designed to withstand environmental loads and meet international standards. This precision engineering minimizes errors during fabrication and assembly, resulting in a seamless construction process and superior end-product.

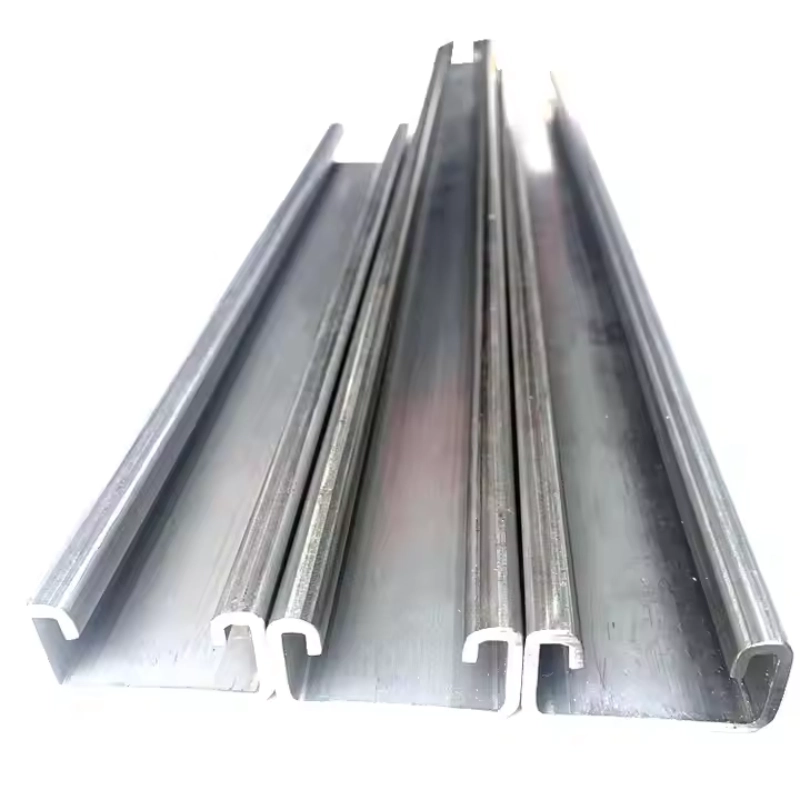

One of the pivotal elements in this process is the use of Carbon U Shaped Steel Channel Steel. This advanced material offers enhanced load-bearing capacity and corrosion resistance, making it ideal for the main frameworks of industrial and commercial buildings. By integrating such high-grade steel components, Honglu ensures that each structure is not only durable but also capable of withstanding harsh conditions.

Advanced Manufacturing Techniques

Honglu’s state-of-the-art manufacturing facilities are equipped with automated machinery and quality control systems. These technologies guarantee that every steel component, including the widely used C shape steel structure, is produced with consistent accuracy. C shape steel structures are favored for their lightweight yet robust profile, making them ideal for columns, beams, and bracing in prefab buildings.

Automation in manufacturing not only boosts efficiency but also drastically reduces the risk of human error. Each batch of steel undergoes rigorous testing for tensile strength, weld integrity, and dimensional accuracy, ensuring that only top-quality materials are delivered to the construction site.

Quality Assurance and Certification

To further guarantee construction quality, Honglu implements a multi-layered quality assurance system. This includes:

- Raw Material Inspection: All steel materials are sourced from certified suppliers and undergo chemical and physical testing.

- In-Process Quality Checks: Every stage of fabrication is monitored, with real-time data collection and analysis.

- Final Product Testing: Completed components are inspected for compliance with both Chinese and international building codes.

Honglu’s dedication to quality is further validated by certifications such as ISO 9001, CE, and other industry-specific accreditations. These certifications provide clients with confidence in the structural reliability and safety of their prefab steel buildings.

Customization and Flexibility

One of the key advantages of working with Honglu is the ability to customize prefab steel buildings to meet diverse project requirements. Whether it’s a warehouse, factory, commercial complex, or agricultural facility, Honglu leverages modular design principles and flexible steel components—like Carbon U Shaped Steel Channel Steel and C shape steel structures—to deliver tailored solutions.

This flexibility not only accelerates the construction timeline but also allows for future expansion or modification with minimal disruption. The modular approach also supports sustainable practices, as components can be reused or recycled at the end of the building’s lifecycle.

Industry Trends: Sustainability and Innovation

The prefab steel building industry is rapidly evolving, with a strong emphasis on sustainability and innovation. Honglu is at the vanguard of this movement, integrating eco-friendly practices throughout its operations. Steel itself is a highly recyclable material, and Honglu’s efficient design and manufacturing processes minimize waste and energy consumption.

Furthermore, the adoption of Building Information Modeling (BIM) and smart construction technologies allows for precise planning, resource optimization, and real-time project management. These advancements not only improve construction quality but also reduce costs and environmental impact.

Global Reach and Collaborative Partnerships

Honglu’s influence extends beyond China, with prefab steel buildings exported to over 60 countries worldwide. The company collaborates with architects, engineers, and developers to deliver turnkey solutions that meet the specific needs of each market. By maintaining strict adherence to global standards and fostering a culture of continuous improvement, Honglu has become a trusted partner for large-scale construction projects across industries.

Industry experts predict that the demand for high-quality prefab steel buildings will continue to rise, driven by urbanization, industrialization, and the need for rapid infrastructure development. Companies like Honglu, with their focus on quality, innovation, and sustainability, are well-positioned to shape the future of construction.

Conclusion: Building the Future with Confidence

Superior construction quality in prefab steel buildings is no accident—it is the result of meticulous engineering, advanced manufacturing, rigorous quality assurance, and a commitment to innovation. Honglu Group exemplifies these principles, utilizing cutting-edge materials such as Carbon U Shaped Steel Channel Steel and C shape steel structure to deliver buildings that are safe, durable, and adaptable.

As the prefab steel building industry continues to evolve, Honglu remains dedicated to exceeding client expectations and setting new standards for excellence. Whether for industrial, commercial, or specialized applications, choosing Honglu means building with confidence—today and for generations to come.

Tags:H Beam H,Steel Garage&Steel Shed,C Steel & Z Steel Purlin,Space Steel Structure