As industrial and commercial projects continue to evolve, the demand for robust, efficient, and long-lasting structures is on the rise. Galvanized steel structures have become the backbone of modern construction, offering unmatched durability and resistance to corrosion. At Honglu Group (abbreviated as Honglu), we understand the importance of maximizing efficiency during the installation process. In this article, we’ll share expert tips for installing galvanized steel structures, insights from leading Equipment Steel Structure factory operations, and industry trends to help you achieve the best results.

Memahami Struktur Baja Galvanis

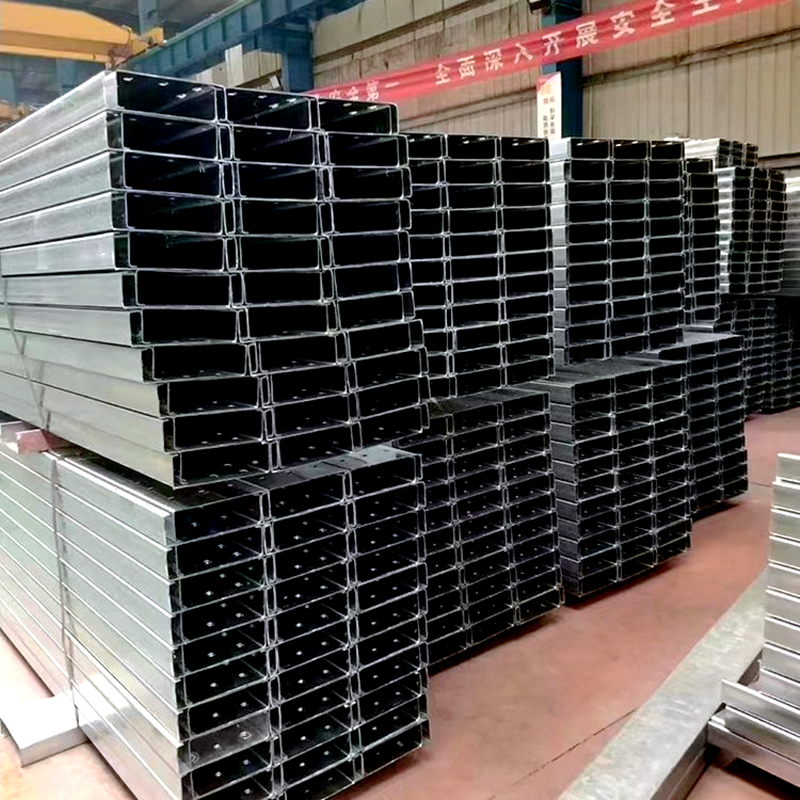

Galvanized steel is steel that has been coated with a protective layer of zinc to prevent rusting. This process significantly extends the life of the structure, making it an ideal choice for factories, warehouses, and equipment enclosures. Honglu, as a trusted Equipment Steel Structure supplier, emphasizes the importance of using high-quality galvanized steel to ensure structural integrity and reduce maintenance costs over time.

Pre-Installation Planning and Preparation

- Site Assessment: Before installation, conduct a thorough site assessment to identify potential challenges such as uneven ground, drainage issues, or obstructions. Proper planning minimizes delays and ensures a smoother workflow.

- Detailed Drawings and Layouts: Collaborate with your Equipment Steel Structure factory to review detailed structural drawings and layouts. Precision at this stage prevents costly mistakes during assembly.

- Material Inspection: Verify that all galvanized steel components meet the required standards and specifications. Check for uniform coating, absence of rust, and correct dimensions.

Efficient Installation Techniques

Efficiency during installation not only saves time but also enhances the overall quality and safety of the structure. Honglu recommends the following techniques:

- Perakitan Modular: Prefabricate as many components as possible at the Equipment Steel Structure factory. Modular assembly reduces on-site labor and speeds up the installation process.

- Proper Fastening: Use high-quality bolts, nuts, and washers designed for galvanized steel. Ensure all fasteners are tightened to the recommended torque to avoid loosening over time.

- Alignment and Leveling: Continuously check the alignment and level of each section during assembly. Misalignment can compromise structural stability and complicate future expansions.

- Protective Measures: Handle galvanized steel with care to avoid damaging the zinc coating. Use padded lifting equipment and avoid dragging components on abrasive surfaces.

Quality Control and Safety Measures

Quality control is paramount in ensuring the longevity and safety of galvanized steel structures. Honglu, as a leading Equipment Steel Structure supplier, integrates rigorous inspection protocols at every stage:

- Weld Inspection: Ensure all welds are smooth, continuous, and free of cracks or porosity. Poor welding can lead to structural weaknesses.

- Coating Integrity: After installation, inspect the zinc coating for scratches or bare spots. Touch up any damaged areas with zinc-rich paint to maintain corrosion resistance.

- Safety Compliance: Adhere to all relevant safety standards and provide proper training for installation teams. Use personal protective equipment (PPE) and follow safe lifting practices.

Optimizing Project Efficiency with Industry Insights

The steel structure industry is constantly evolving, with new technologies and practices emerging to enhance efficiency. Here are some industry-related insights to further optimize your project:

- Digital Project Management: Utilize Building Information Modeling (BIM) and digital project management tools to streamline communication and track progress in real time.

- Sustainability Trends: Many Equipment Steel Structure factories are adopting sustainable manufacturing practices, such as recycling steel and reducing energy consumption. Choosing a supplier like Honglu that prioritizes sustainability can benefit your project and the environment.

- Customization and Flexibility: Modern galvanized steel structures offer a high degree of customization. Work closely with your supplier to tailor designs that meet specific operational needs while allowing for future scalability.

Choosing the Right Equipment Steel Structure Supplier

Selecting a reliable supplier is crucial for project success. Honglu Group stands out among Equipment Steel Structure suppliers due to its commitment to quality, innovation, and customer satisfaction. When evaluating suppliers, consider the following:

- Experience and Reputation: Look for a supplier with a proven track record and positive client testimonials.

- Production Capabilities: Ensure the supplier’s factory can handle your project’s scale and complexity.

- Dukungan Purnajual: Opt for companies that offer comprehensive after-sales services, including maintenance, repairs, and technical guidance.

Table: Key Advantages of Galvanized Steel Structures

| Advantage | Keterangan |

|---|---|

| Ketahanan Korosi | Galvanized coating protects against rust, extending lifespan. |

| Low Maintenance | Requires minimal upkeep, reducing long-term costs. |

| High Strength-to-Weight Ratio | Provides robust support without excessive weight. |

| Perakitan Mudah | Prefabricated components enable quick installation. |

| Keserbagunaan | Suitable for a wide range of industrial and commercial applications. |

Kesimpulan

Maximizing efficiency in the installation of galvanized steel structures requires a strategic approach, from initial planning to final inspection. By following these expert tips and leveraging the expertise of a reputable Equipment Steel Structure supplier like Honglu, you can ensure your project is completed on time, within budget, and to the highest standards of quality. As the industry continues to advance, staying informed about new technologies and best practices will keep your operations competitive and future-ready.

For more information about our products and services, or to consult with our engineering team, contact Honglu Group today. Let us help you build the future with strength and efficiency.

Tag::Struktur Baja Peralatan,pelat dek rangka batang baja,Garasi Baja & Gudang Baja,Struktur Baja Jembatan