In the fast-evolving construction industry, the demand for durable and cost-effective building solutions is higher than ever. As a leading Steel Structure System manufacturer, Honglu Group (abbreviated as Honglu) has consistently delivered innovative steel structure systems that address both performance and economic concerns. One of the most frequently asked questions by project owners and developers is whether galvanized steel structures can truly reduce long-term maintenance costs. In this article, we delve into this topic, exploring the benefits, industry trends, and Honglu’s expertise as a renowned Steel Structure System factory.

Understanding Galvanized Steel Structures

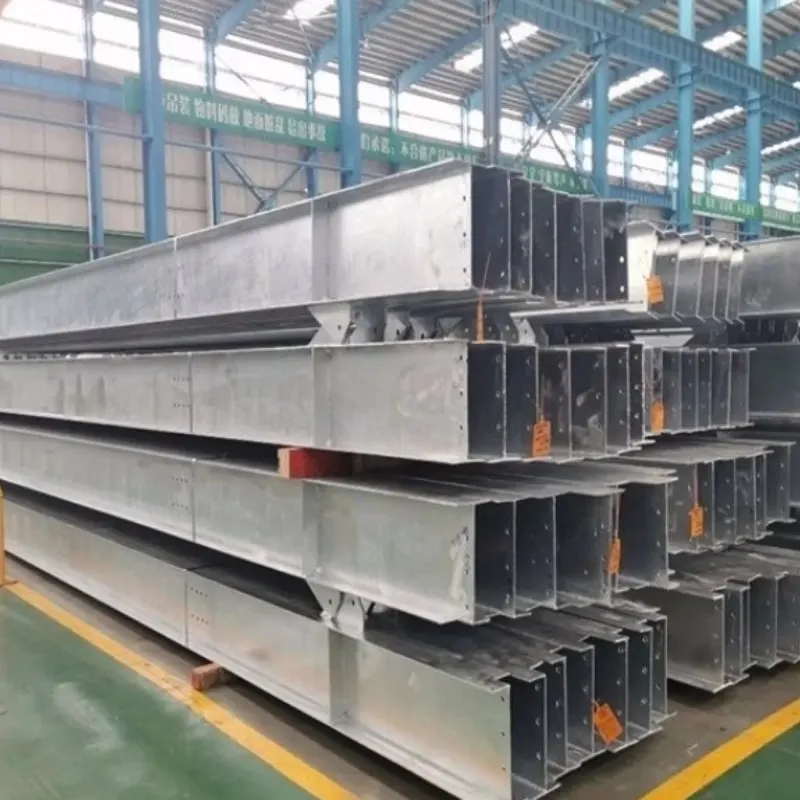

Galvanized steel structures are fabricated using steel components that are coated with a protective layer of zinc. This process, known as galvanization, significantly enhances the steel’s resistance to corrosion, rust, and environmental damage. The zinc coating acts as a barrier, preventing moisture and chemicals from reaching the underlying steel, thereby extending the lifespan of the structure.

For companies like Honglu, which specializes in the design, manufacturing, and installation of steel structure systems, the adoption of galvanized steel is a strategic move. It ensures that their products not only meet stringent quality standards but also deliver tangible long-term benefits to clients.

The Cost Dynamics: Initial Investment vs. Maintenance

One of the most significant advantages of choosing galvanized steel structures is the reduction in maintenance costs over the lifespan of a building or facility. While the initial investment in galvanized steel may be slightly higher compared to non-galvanized alternatives, the long-term savings are substantial.

- Corrosion Resistance: Galvanized steel’s superior resistance to rust and corrosion reduces the need for frequent repairs and repainting.

- Extended Lifespan: Structures made from galvanized steel can last several decades with minimal maintenance, making them ideal for industrial, commercial, and infrastructure projects.

- Minimal Downtime: Reduced maintenance requirements mean less operational downtime, which is especially critical for factories and warehouses.

According to industry research, maintenance costs for non-galvanized steel structures can be up to three times higher over a 20-year period compared to their galvanized counterparts. For large-scale projects, this cost differential can translate into significant savings.

Honglu’s Approach as a Steel Structure System Manufacturer

As a reputable Steel Structure System manufacturer, Honglu has invested heavily in advanced galvanization technology and quality control processes. Their state-of-the-art facilities enable them to produce steel components with uniform zinc coatings, ensuring consistent performance and durability.

Honglu’s engineering team works closely with clients to design steel structure systems tailored to specific environmental conditions and project requirements. Whether for coastal regions with high humidity or industrial sites exposed to chemicals, Honglu’s galvanized solutions are engineered to withstand the harshest conditions with minimal maintenance.

Industry Trends: The Shift Toward Sustainable Steel Construction

The global construction industry is witnessing a paradigm shift toward sustainability and lifecycle cost optimization. Galvanized steel structures align perfectly with these trends, offering not only reduced maintenance costs but also enhanced recyclability and environmental performance. Many governments and regulatory bodies are now encouraging the use of galvanized steel in public infrastructure projects to promote long-term asset durability and resource efficiency.

As a leading Steel Structure System factory, Honglu is at the forefront of these industry trends. The company’s commitment to sustainable practices extends to its manufacturing processes, with a focus on reducing waste, optimizing energy consumption, and maximizing the recyclability of steel components.

Comparative Table: Maintenance Costs Over Time

| Structure Type | Initial Cost | Maintenance Cost (20 Years) | Total Cost |

|---|---|---|---|

| Non-Galvanized Steel | Lower | High | Highest |

| Galvanized Steel | Moderate | Low | Lowest |

This table clearly illustrates the economic advantage of galvanized steel structures over time, supporting the case for their adoption in a wide range of applications.

Real-World Applications and Success Stories

Honglu’s portfolio includes numerous successful projects where galvanized steel structures have delivered exceptional performance and cost savings. From large-scale logistics centers and manufacturing plants to commercial complexes and public infrastructure, Honglu’s clients consistently report reduced maintenance interventions and lower lifecycle costs.

In one notable example, a logistics park developed by Honglu in a coastal city faced extreme humidity and salt exposure. By utilizing galvanized steel structures, the facility has operated for over a decade with minimal maintenance, resulting in significant cost savings and uninterrupted operations.

Choosing the Right Partner: Why Honglu?

When it comes to selecting a Steel Structure System manufacturer or Steel Structure System factory, the expertise and track record of the provider are crucial. Honglu’s integrated approach—from design and fabrication to installation and after-sales support—ensures that clients receive not only high-quality galvanized steel structures but also comprehensive guidance on maintenance optimization.

- Custom Engineering: Solutions tailored to project-specific needs and environmental challenges.

- Advanced Galvanization: State-of-the-art coating processes for maximum durability.

- End-to-End Support: Professional consultation, installation, and maintenance services.

Conclusion: Galvanized Steel Structures as a Smart Investment

In summary, galvanized steel structures offer a compelling solution for reducing maintenance costs, extending asset lifespan, and supporting sustainable construction practices. As demonstrated by Honglu’s extensive experience as a Steel Structure System manufacturer and Steel Structure System factory, the long-term economic and operational benefits far outweigh the initial investment. For project owners and developers seeking to optimize their building assets, partnering with an industry leader like Honglu ensures both peace of mind and a strong return on investment.

For more information on how Honglu’s galvanized steel structure systems can benefit your next project, contact their expert team today.

Tags:H Beam H,C Steel & Z Steel Purlin,floor decking system,Steel Structure price